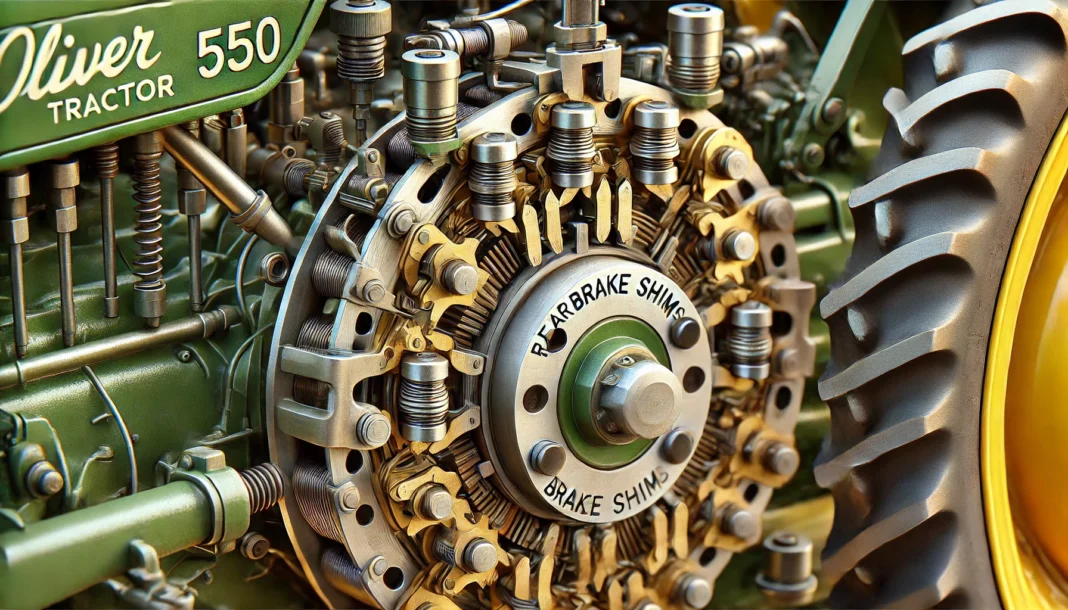

Rear brake shims on a 550 Oliver tractor are critical components that can make or break your farming day. I’ve spent years working with these machines, and I’m gonna share everything you need to know about getting these sorted right.

Understanding Rear Brake Shims on a 550 Oliver Tractor

When we’re talking about rear brake shims on a 550 Oliver tractor, we’re dealing with precision parts that do a massive job. These thin metal spacers sit between your brake components, making sure everything lines up perfectly.

Here’s the real deal about why they matter:

- They prevent uneven brake wear

- They stop that annoying brake drag

- They make sure both wheels brake at the same time

- They help your brake shoes last longer

- They keep your wallet happy by preventing bigger issues

Signs Your 550 Oliver Needs Brake Shim Attention

I remember working on Jim’s 550 last summer – he thought he needed a full brake job, but it was just poorly adjusted shims. Here’s what to watch for:

- Your tractor yanks to one side during braking

- You’re hearing metal-on-metal sounds

- The brake pedal feels mushy or weird

- One wheel’s running hotter than its mate

- Your brakes are dragging when you’re not even touching them

- You notice uneven tire wear

- The brake pedal travel isn’t what it used to be

Getting Ready for the Job

Before you crack into those rear brake shims on a 550 Oliver tractor, get your gear sorted:

Essential Tools:

- Complete spanner set

- Accurate feeler gauge

- Fresh shims in various sizes

- Heavy-duty jack and stands

- Eye protection

- Work gloves

- Brake cleaner

- Wire brush

- Good lighting setup

Nice-to-Haves:

- Brake spring pliers

- Proper brake adjustment tools

- Impact wrench

- Torque wrench

- Parts cleaning tank

The Step-by-Step Fix

- Safety First

- Park on solid, level ground

- Chock the front wheels

- Make sure your jack points are solid

- Getting Access

- Jack up the rear end properly

- Secure with good stands

- Pull both rear wheels

- Mark your parts for reassembly

- Brake Drum Removal

- Take photos for reference

- Remove the keeper pins

- Pull drums carefully

- Don’t drop anything

- Shim Assessment

- Check existing shim thickness

- Look for wear patterns

- Measure all clearances

- Document everything

- The Actual Shimming

- Clean all surfaces properly

- Start with thinner shims

- Test fit everything

- Add thickness as needed

- Check both sides match

- Reassembly Tips

- Use new keepers if needed

- Check spring tension

- Verify free movement

- Test before wheel mounting

Real Talk About Common Mistakes

I’ve seen plenty go wrong with rear brake shims on 550 Oliver tractors:

- Rushing the job and missing crucial measurements

- Using damaged or bent shims

- Forgetting to check both sides

- Over-tightening adjustments

- Not cleaning parts properly

- Mixing up left and right components

Pro Tips from Years in the Field

Here’s what I’ve learned:

- Keep a set of spare shims handy

- Always work on both sides

- Clean everything twice

- Check your work before final assembly

- Test thoroughly before heavy use

Your Burning Questions Answered

Q: How do I know exactly when to replace brake shims? A: Check them during regular maintenance or when braking performance changes

Q: What’s the correct shimming sequence? A: Start thin, add layers until you hit the right clearance

Q: Can weather affect brake shim performance? A: Yes, especially in wet or muddy conditions

Q: Should I replace all shims at once? A: Usually best to do both sides together

Special Considerations for Different Conditions

Farm Work:

- Check more often in dusty conditions

- Watch for mud build-up

- Clean more frequently

Road Use:

- Balance is extra important

- Regular adjustment checks needed

- More frequent inspection intervals

When to Call for Backup

Know your limits. Get professional help if:

- You find serious wear

- Adjustments won’t stay put

- You spot oil contamination

- The job gets complicated

- You’re not 100% sure

Prevention Better Than Cure

Regular maintenance of rear brake shims on a 550 Oliver tractor saves time and money:

- Monthly visual checks

- Regular cleaning

- Proper adjustment maintenance

- Documentation of changes

- Keeping spare parts handy

Remember: Getting your rear brake shims right on a 550 Oliver tractor isn’t just about the fix – it’s about keeping your machine running safely and efficiently for years to come. Take your time, do it right, and you’ll save yourself headaches down the road.